-

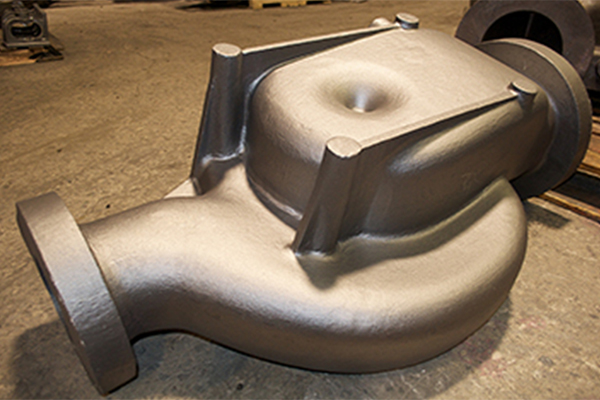

Ferrous Castings

From 1 to 4500 lbs castings in a variety of ferrous alloys including duplex stainless

steels. Casings are manufactured and designed for all industries.

-

Patterns

Precision pattern making using traditional methods and 3D CNC processes.

-

Casting Simulation

Pushing the technology boundaries that others are still struggling to learn. The

future is great. We have already simulated it.

-

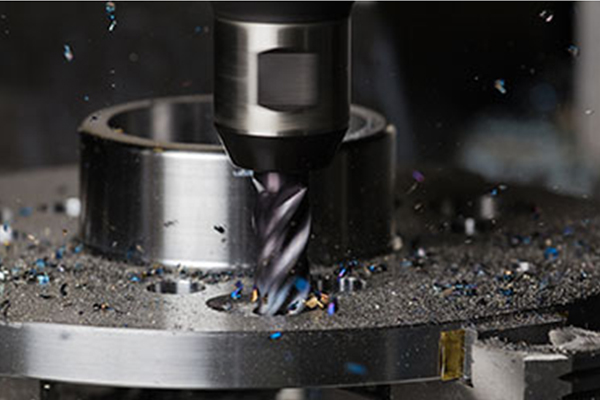

Machining

Add value to your castings with a full spectrum of machining capabilities and options.

Turn your project into a turnkey project.

-

Non-Destructive Testing

A full line of testing is available for added assurance including liquid penetrant,

magnetic particle, ultrasonic and radiography.

-

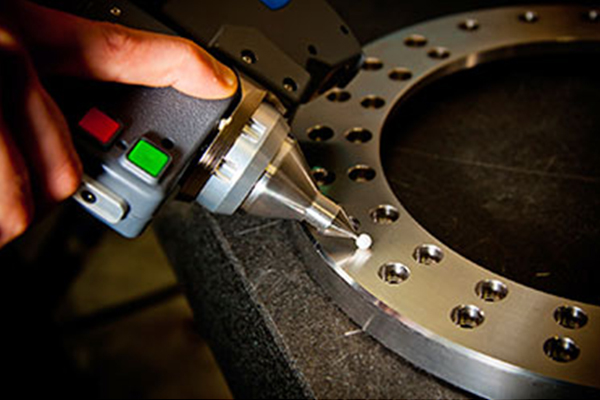

Inspection

High tolerance dimensional inspection of patterns and castings using state of the

art metrology using a FARO arm with laser scanner.

-

ASME Certified Welding

For each Alloy that we pour there is a weld procedure. All stick and MIG procedures

are qualified in accordance with ASME Section IX.

-

Heat Treating

PLC controlled furnaces ensure accurate cycles. Heat temperatures and times are

stored electronically for traceability and verification.

-

Sand & Shot Blasting

The appropriate blast medium is carefully selected for each alloy and casting to

ensure a consistent and superior surface finish.